Progressive die stamping is a cornerstone in metal fabrication. But beyond the obvious, what subtle nuances should one consider for optimal results? Dive into the intricacies of size, complexity, and volumes required, as well as the often-overlooked subtleties of the process.

The primary elements to consider in progressive die stamping are the size of the part, its complexity, and the volumes required. However, delving deeper reveals nuances like material grain direction, lubrication, and environmental factors that can significantly influence the outcome.

To master the art of progressive die stamping, a comprehensive understanding of both the obvious and the subtle is essential. Let’s explore.

The Significance of Size in Progressive Die Stamping

Size plays a pivotal role in progressive die stamping. It not only dictates the design and feasibility of the part but also influences the choice of machinery, material consumption, and the overall quality of the finished product. Let’s delve deeper into the nuances of size in this process.

Size Constraints and Machine Capabilities

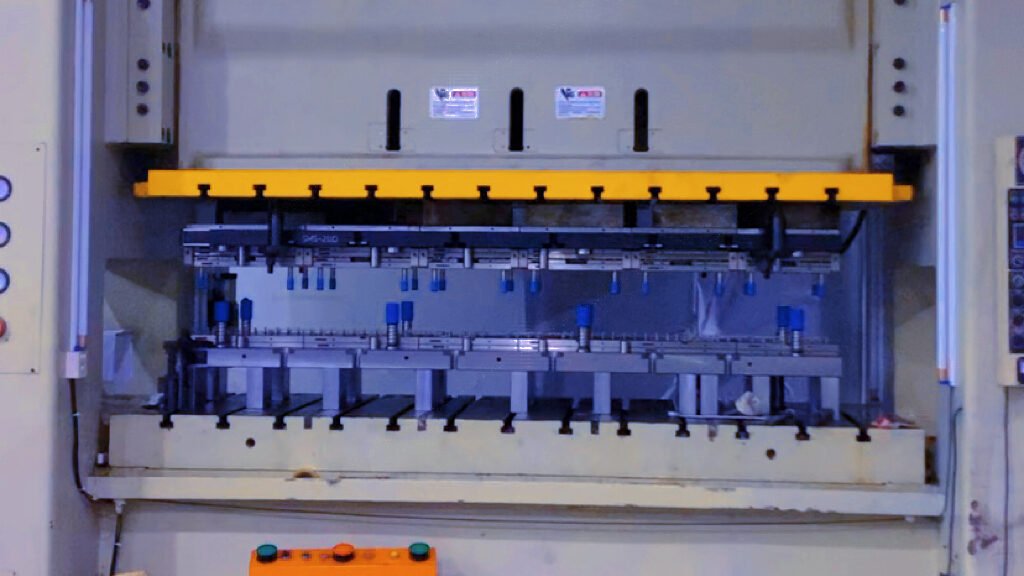

The size of the part to be stamped largely determines the type of machinery that can be used. Larger parts require bigger presses with higher tonnage, while smaller, intricate parts might be better suited for smaller presses that offer more precision.

- Machinery Limitations: Each stamping machine has its own set of capabilities and limitations. For instance, a press with a 100-ton capacity might not be suitable for stamping a large automotive part that requires 300 tons of force.

- Die Size and Complexity: The size of the part also dictates the size and complexity of the die. Larger parts require larger dies, which can be more challenging to design and manufacture.

Impact on Material Usage

The size of the stamped part directly affects the amount of material used. Larger parts consume more material, leading to increased costs. However, with efficient design and layout, wastage can be minimized.

- Sheet Metal Utilization: Proper layout ensures maximum parts can be stamped out of a single sheet, reducing waste.

- Material Thickness: The size and function of the part might also dictate the thickness of the material used. For instance, a larger structural component might require thicker metal for added strength, while a small decorative piece might use thinner metal.

Size and Tolerance Levels

Tolerance levels, or the allowable deviation from the specified dimensions, are crucial in stamping. The size of the part can influence these levels.

- Precision Requirements: Smaller parts, especially those used in electronics or medical devices, often have stricter tolerance levels due to the need for high precision.

- Measurement Challenges: Larger parts might present challenges in measurement and inspection, especially if they have complex geometries.

In conclusion, the size of the part being stamped has a profound impact on various aspects of the progressive die stamping process. From machine selection to material consumption and quality control, understanding the significance of size is crucial for successful stamping.

Complexity: More Than Just Design

Complexity in progressive die stamping extends beyond mere design intricacies. It encompasses the challenges in die design, the implications on production speed, and the hurdles faced when dealing with highly intricate parts. Let’s explore the multifaceted nature of complexity in this context.

Design Intricacies and Die Design

The complexity of a part’s design directly influences the design of the die. Intricate designs demand dies that can handle detailed shapes, curves, and angles.

- Multi-Stage Dies: For highly complex parts, multi-stage dies might be required. These dies perform several operations in a sequence, allowing for the creation of detailed parts in a single pass.

- Precision and Accuracy: The more intricate the design, the higher the precision required in the die. This ensures that every stamped part matches the intended design without deviations.

Complexity and Production Speed

The intricacy of a part can influence the speed at which it’s produced. More complex parts often require slower production speeds to ensure accuracy.

- Slower Press Speeds: Complex designs might necessitate slower press speeds to allow for precise stamping and to prevent errors.

- Increased Inspection Time: Intricate parts often require more time for inspection and quality control, ensuring that every detail is correctly stamped.

Challenges with Highly Complex Parts

Stamping highly intricate parts presents its own set of challenges, from material choice to post-stamping processes.

- Material Selection: Complex parts might require specific materials that can handle the intricacies without tearing or deforming.

- Post-Stamping Processes: Highly detailed parts might need additional post-stamping processes, such as deburring or secondary bending, to achieve the final desired shape.

- Tool Wear: The tools and dies used for intricate parts tend to wear out faster due to the detailed work they perform. This necessitates regular maintenance and, in some cases, more frequent replacements.

In essence, while complexity adds value and functionality to stamped parts, it also introduces challenges that manufacturers must address. Balancing design intricacies with production efficiency and quality is key to mastering the art of stamping complex parts.

Volumes Required: Balancing Demand and Production

The volume of parts required plays a significant role in the progressive die stamping process. It not only determines the scale of production but also influences cost considerations and the wear and tear on machinery. Let’s delve into how production volumes intersect with these factors.

Production Runs and Cost Implications

The number of parts needed directly impacts the cost per unit and the setup of the stamping process.

- Economies of Scale: Larger production runs often benefit from economies of scale. The cost per unit tends to decrease as the number of parts produced increases, primarily because the setup costs are distributed over a larger number of units.

- Setup and Changeover Time: For smaller production runs, the setup and changeover times can significantly influence the cost. If frequent die changes are required for different parts, it can increase the production time and associated costs.

Volumes and Machine Wear

The volume of parts being stamped has a direct correlation with the wear and tear on the stamping machinery.

- Frequent Use: Machines that are constantly in use for high-volume production runs experience faster wear. This can lead to more frequent maintenance requirements and potential downtimes.

- Die Wear: The dies used in the stamping process are subject to wear and tear, especially in high-volume production. Over time, this wear can affect the quality of the stamped parts, necessitating regular die maintenance or replacement.

- Optimal Machine Operation: Running a machine continuously at its maximum capacity can lead to overheating and increased wear. It’s essential to balance the production volumes with optimal machine operation to ensure longevity and consistent quality.

In conclusion, while high production volumes can offer cost benefits, they also present challenges in terms of machine wear and maintenance. Striking a balance between demand and production, while ensuring quality and efficiency, is crucial in the progressive die stamping process.

The Nuances of Progressive Die Stamping

Progressive die stamping is a multifaceted process, influenced by a myriad of factors beyond the basic mechanics. From the grain direction of metals to the skill level of the operator, let’s explore the subtle nuances that can significantly impact the outcome of the stamping process.

Material Grain Direction: Understanding how the grain direction of metals affects the stamping process.

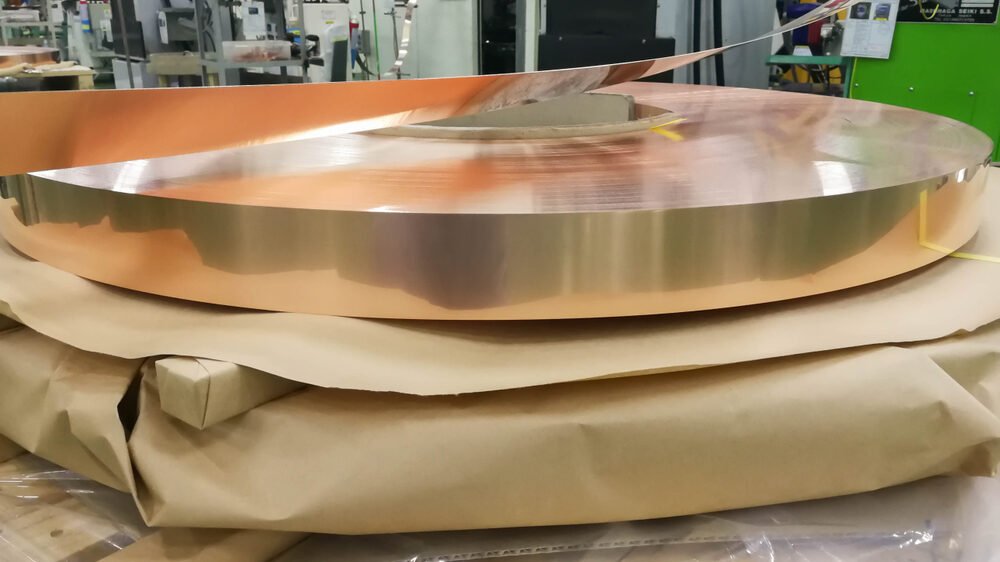

Every metal sheet has a grain direction, which is the orientation of the crystalline structure. This direction can influence the metal’s strength, flexibility, and finish.

- Strength and Flexibility: Stamping along the grain direction can enhance the metal’s strength but reduce its flexibility. Conversely, stamping against the grain can increase flexibility but reduce strength.

- Surface Finish: The grain direction can also affect the final surface finish of the stamped part, with potential implications for aesthetics and functionality.

Lubrication in Stamping: The importance of proper lubrication and its impact on stamping quality.

Lubrication plays a pivotal role in ensuring smooth stamping operations and enhancing the lifespan of the dies.

- Reducing Friction: Proper lubrication reduces friction between the die and the metal, preventing tearing and ensuring a clean cut.

- Die Longevity: Lubrication minimizes wear and tear on the die, extending its operational life and reducing maintenance costs.

Die Maintenance and Storage: Ensuring the longevity and efficiency of dies through proper maintenance and storage.

Regular maintenance and proper storage are crucial for the longevity and efficiency of stamping dies.

- Regular Inspection: Dies should be inspected regularly for signs of wear, damage, or misalignment. Timely repairs can prevent costly breakdowns and ensure consistent stamping quality.

- Proper Storage: Storing dies in a clean, dry environment prevents corrosion and damage, ensuring they remain in optimal condition for future use.

Temperature and Environmental Factors: How external conditions can influence the stamping process.

The ambient temperature and environmental conditions can have a profound impact on the stamping process.

- Metal Behavior: Metals can expand or contract with temperature changes, affecting their behavior during stamping.

- Lubrication Viscosity: The viscosity of lubricants can vary with temperature, influencing their effectiveness.

- Humidity Concerns: High humidity can lead to corrosion, especially for certain metals, affecting the quality of the stamped parts.

Human Factors and Training: The role of operator skill and experience in ensuring stamping success.

The human element is crucial in the stamping process. The skill, experience, and training of the operator can significantly influence the outcome.

- Skill and Precision: A skilled operator can optimize the stamping process, ensuring precision and minimizing errors.

- Training and Safety: Proper training is essential not only for quality but also for safety. An adequately trained operator can prevent accidents and ensure smooth operations.

- Problem Solving: Experienced operators can quickly identify and rectify issues, ensuring consistent quality and minimizing downtime.

In essence, the nuances of progressive die stamping are as critical as the primary factors. By understanding and addressing these subtleties, manufacturers can achieve unparalleled precision and quality in their stamped parts.

Real-world Applications in the Electronics Industry

The electronics industry, with its demand for precision, durability, and scalability, heavily relies on progressive die stamping. This method offers the ability to produce intricate parts in large volumes while maintaining consistent quality. Let’s explore some real-world applications of progressive die stamping in the electronics sector.

Mobile Devices

Mobile devices, especially smartphones, are marvels of engineering, packing numerous components into a compact form. Progressive die stamping plays a crucial role in their manufacturing.

- Apple iPhones: One of the industry leaders, Apple, utilizes progressive die stamping for various internal metal components. This includes parts like battery clips, which ensure stable battery connections, and SIM card trays, which need to be durable and precisely shaped for easy insertion and removal.

Computer Hardware

Computers and their peripherals contain numerous metal components that require precision manufacturing.

- Samsung SSDs: Solid State Drives (SSDs) are becoming the standard for computer storage. Samsung, a leading SSD manufacturer, uses progressive die stamping for the metal casings of their drives. These casings not only protect the delicate internal components but also aid in heat dissipation, ensuring the drive’s longevity and performance.

Connectors and Sockets

Connectors and sockets are fundamental in electronics, ensuring seamless and reliable connections between various components.

- Molex Connectors: Molex is a renowned name in the connector industry. Their connectors, widely used in electronics ranging from computers to automotive applications, often have metal contact pins made using progressive die stamping. This ensures precise electrical connections, vital for the reliable functioning of electronic devices.

Audio Equipment

The audio industry demands precision for delivering high-quality sound. Progressive die stamping aids in achieving this precision.

- High-end Headphones: Brands like Sony, known for their audio equipment, utilize progressive die stamping for components in their high-end headphones. For instance, audio driver components, which are pivotal for sound reproduction, are often produced using this method. This ensures high-fidelity sound reproduction, delivering a premium audio experience to the user.

In conclusion, the electronics industry, with its emphasis on precision, durability, and scalability, finds a reliable ally in progressive die stamping. From mobile devices to audio equipment, this manufacturing method ensures that electronic products are both functional and durable.

Delving Deeper: Unanswered Questions in Progressive Die Stamping

Progressive die stamping, while a widely adopted manufacturing method, still has areas that raise questions and demand deeper understanding. From material choices to post-processing, let’s delve into some of these unanswered questions and explore the intricacies involved.

Material Choices and Their Implications

The choice of material in stamping is pivotal, influencing both the process and the final product. Different materials come with their unique set of properties, which can significantly affect the stamping outcome.

- Influence on Stamping Process: Materials like aluminum, known for their malleability, might be easier to stamp but can be prone to tearing if not handled correctly. On the other hand, harder materials like stainless steel require more force but offer durability. Understanding these nuances is crucial for a successful stamping process.

- Balancing Quality and Cost: High-quality materials often come with a higher price tag. Manufacturers must strike a balance between using top-notch materials and managing the overall project costs. This involves assessing the part’s function, its longevity requirements, and the budget constraints.

Equipment Selection for Specific Needs

The machinery used in progressive die stamping plays a significant role in determining the quality and efficiency of the process.

- Machines for Different Designs: Not all stamping machines are created equal. Intricate designs might require specialized equipment capable of handling detailed work with precision. Selecting the right machinery is paramount to ensure the desired outcome.

- Technological Advancements: The world of manufacturing is continually evolving, with new machines and techniques emerging. Modern equipment, often equipped with computerized controls and sensors, can enhance the stamping process, especially for complex projects, ensuring precision and reducing wastage.

Post-Processing: Ensuring Quality Beyond Stamping

Stamping is just one part of the manufacturing journey. Ensuring the quality of stamped parts and addressing any defects is equally crucial.

- Quality Checks: Once parts are stamped, they undergo rigorous quality checks. Methods like visual inspection, dimensional checks, and even advanced techniques like X-ray inspection can be employed to ensure the parts meet the desired standards.

- Addressing Defects: No process is entirely foolproof. There might be instances where defects arise in stamped parts. Strategies to identify these defects, analyze their root causes, and rectify them are essential. This might involve re-stamping, secondary processes, or even tweaking the initial stamping setup.

In essence, while progressive die stamping is a powerful manufacturing method, it’s the attention to these finer details that ensures its success. From material selection to post-processing, understanding and addressing these unanswered questions can elevate the quality and efficiency of the stamping process.

Conclusion

Progressive die stamping stands at the intersection of meticulous planning, precise execution, and deep understanding of materials and processes. It’s not just about applying force to a piece of metal; it’s about doing so in a manner that ensures the final product meets exacting standards of quality, durability, and functionality.

The primary factors, such as material choice, machinery selection, and design intricacies, lay the foundation for the process. However, it’s the subtle nuances, like understanding material grain direction, ensuring proper lubrication, and addressing post-stamping defects, that elevate the process from mere manufacturing to a craft.

Moreover, the real-world applications of this method, especially in industries like electronics, underscore its significance. From the tiny SIM card tray in our phones to the connectors that power our devices, progressive die stamping touches our lives in myriad ways.

In essence, progressive die stamping is more than just a manufacturing technique; it’s a testament to human ingenuity and the relentless pursuit of perfection. By understanding and respecting both its art and science, manufacturers can continue to push the boundaries of what’s possible, crafting parts that are not only functional but also exemplify excellence in design and execution.