Deep draw manufacturing forms sheets of metal into the desired shape by pressing it between two punch and die pieces.

Unlike punching or forging, the deep draw process canbe used withalmost any thickness of material, making deep draw the obvious choice for large or difficult to produce products. For example, manufacturing small diameter tube sheets for nuclear reactors, gear housings, trunk lids, automobile body panels, and automotive suspension components—anything requiring high formability and ultimate tensile strength.

Deep draw is suitable for low-cost materials such as steel, copper alloys, aluminum alloys, magnesium alloys, and brass. It can also be used on expensive metals if economic considerations are met.

Deep Draw Stamping Offers the Following 15 Benefits

Conservesenergy in the production process.

Deep draw stamping as a metal forming process requires less energy than other metalworking processes, such as punching or forging.

Metal drawing to form metal shapes has been known for more than a century and grew out of the ancient art of wire drawing. The advantage of this process is that no scrap is produced, and only one operation is required.

Maximizes part strength.

Material flow optimization is a deep draw feature that produces high strengths in thin-walled parts, which can be further enhanced by applying cold forming, such as bending or rolling.

The energy used in the deep draw process is concentrated at the punch tip, so higher compressive residual stresses are developed at the end of the draw radius. This makes it possible to increase the initial blank’s thickness until sufficient strength can be achieved without the risk of degrading its formability.

Improvesthe surface quality of your parts.

Other metalworking processes, such as spinning or stamping, which are often used for thin-walled parts, can deform the shape of the sheet or its contour. This results in degraded surface quality,such as wrinkles on the sheet’s surface. Deep drawing is based upon stretching the material at right angles to its plane,thus avoiding wrinkles on large flat surfaces, which significantly improves the part’s appearance.

Deep drawing is used for various metal sheets and strips, including carbon steel, alloy steel, stainless steel, copper-based alloys, aluminum alloys, and titanium.

Carbon steels are generally cold worked with hot-working die steels used to reduce the forming loads. Aluminum alloys are cold-drawn because these materials respond well.. Deep drawing is essential in aluminum die-casting processes that produce complex parts such as gear housings or enclosures for electronic devices.

Minimizes costs and increases capacity.

The process of deep drawing is readily automated using modern industrial equipment, which helps manufacturers minimize the cost of production by cutting production time and scrap generation rates.

Special tooling and fixtures can optimize material flow during the deep draw process, which helps to generate the optimal blank shape and reduce metal deformation, both of which affect part quality and process efficiency.

Enhance freedom of design.

Deep draw offers greater design freedom because this forming method offers greater flexibility when compared to other standard sheet-forming processes, many of which require much more expensive tools, dies, presses, etc., to achieve similar results.

Deep draw stamping allows an acceptable degree of tolerance for producing even complex shapes from steel or aluminum sheet.

Suitable for a variety of components.

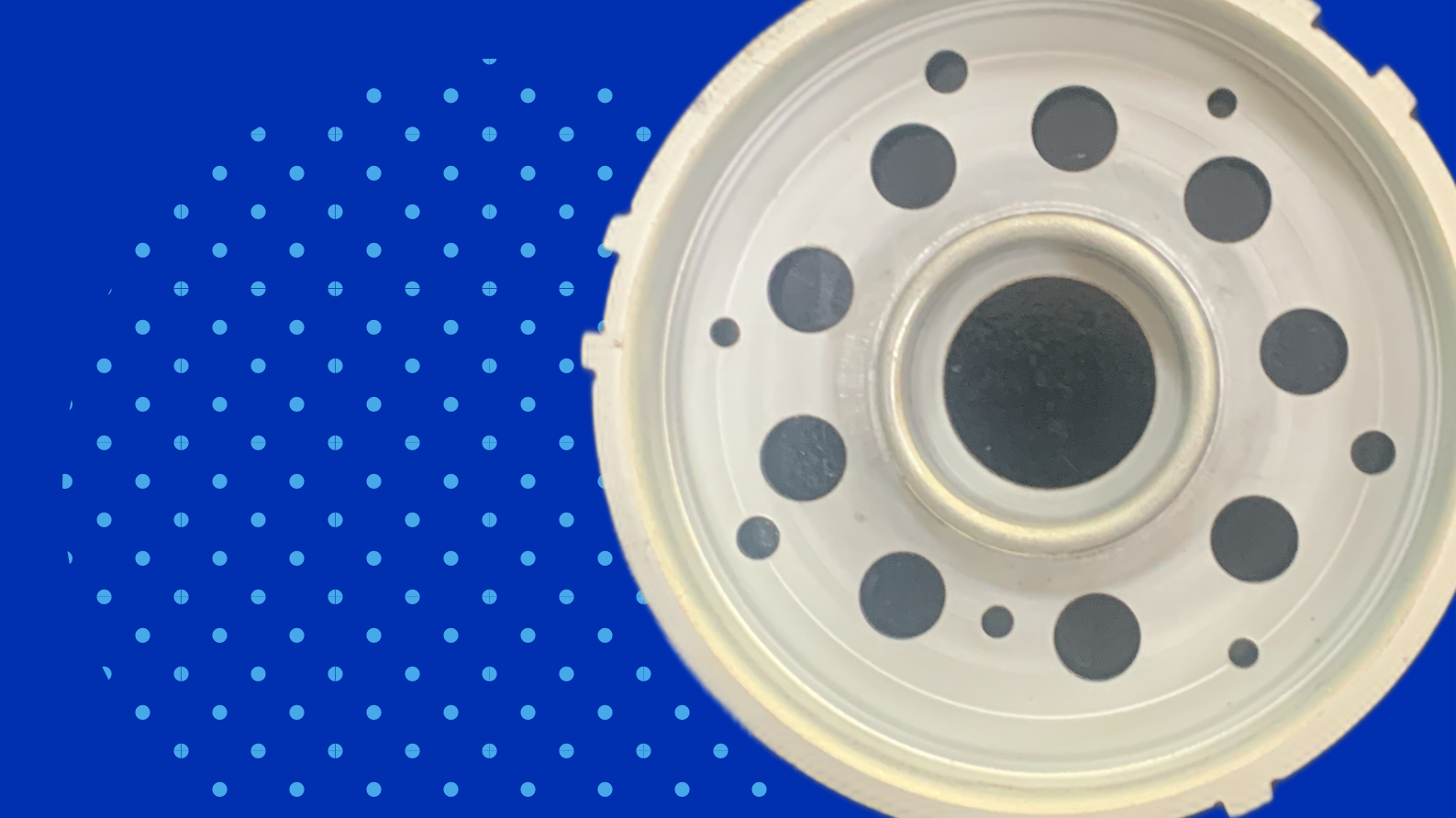

Deep drawing is most often used to make cylindrical parts, such as bottle caps and cans, but also can be used to produce square or rectangular bar stock.

It is a typical process used in manufacturing various automotive components, including fuel tanks and transmission cases. Die design requires the consideration of many interacting factors, which makes deep draw one of the most challenging in the entire manufacturing process, from blanking to final assembly.

Uses less force and energy.

In the deep draw process, material flow around the punch tip is controlled by progressively forming successive hemispherical cavities behind a circular punch. The workpiece material flows away from the punch tip through gaps between adjacent pairs of consecutive holes in an inward direction. With each cavity being semi-spherical, the material flow is partially curling or helically bending around the rotating punch tip.

The drawing force required to form the blank progressively decreases as this curling action continues, reaching a minimum value when the die surface of the fully formed hemispherical cavity comes into contact with the workpiece material.

Reduces scrap.

Scrap generated using the deep draw method is minimized by the highly efficient material flow pattern around the punch tip, which helps reduce scrap material ejected from the die cavity through feeding slots between adjacent cavities. Waste during the punching stage is significantly reduced since workpiece material need not be removed.

Scrap generated during the drawing process is also minimized because of a progressive action that starts with lower forming forces until the material assumes the shape of the die cavity. As the depth of the cavity increases, so does its diameter. This helps further reduce scrap by causing any excess material to be forced out through thinner cross-sections at entry slots located between adjacent semi-spherical cavities.

The walls of each successive hemisphere are thicker than those corresponding to previous cavities, making their removal more efficient than other techniques such as pressing or stamping, where substantial energy is required for punching out greater thicknesses of material.

Forms large parts.

Large items can be formed using deep drawing because of its progressive nature.

The process starts at the bottom part and gradually works its way up to the final stages. This means that scrap generated in this form of manufacture is reduced compared with stamping or press forming processes where shearing or blanking off are typically needed, respectively.

Minimizes mold costs.

The progressive nature of deep drawing means that a single forming die may be used most timesas the process begins with a small diameter that progressively increases to produce the product’s desired final size.

The number of required artwork changes is minimized because the progressive drawing process starts with small holes used to create the form. Smaller hole sizes mean using smaller tools, which reduces tooling costs.

The process works well for producing symmetrical parts, which are subsequently formed into asymmetric shapes. One classic example is the manufacture of beverage cans, where deep drawing achieves the required final shape.

Minimizesthe need for secondary processing.

As each level of material curling occurs around the punch tip, not only does this help to minimize scrap, but it also leads to a progressively increasing thickness in the component being formed. This means that fewer secondary machining operations are needed than other techniques, such as forging, where a progressive reduction is required.

The progressive nature of the process also helps to ensure that all internal cavities are well-formed without requiring additional methods, such as reaming, which would cause further reduction in wall thickness.

Achieve strong yet thin walls.

Deep-drawn components are formed from materials of varying thicknesses. Because of this, they may exhibit thinner wall sections than their press-formed counterparts because the metal flow occurs in an inward direction towards thicker cross-sections. This reduces potential weaknesses associated with sharp corners and increases resistance to external forces applied during use.

The metal has more time to redistribute stresses throughout its structure without buckling or deforming excessively under load.

Achieve strict tolerances.

Tolerances for parts produced using deep drawing can be held easily within standard limits. This is especially beneficial for manufacturers who need to make large items.

Produce intricate details.

The progressive forming method of the deep draw process can form a variety of complex shapes. Although the process starts with shallow surfaces, deepdrawn components often exhibit deeper features when compared with other techniques, such as stamping or forging, where only a single dimension is reduced relative to the original stock material’s size. Because these processes start with larger surface areas, they do not achieve as much part geometry depth as progressive actions that achieve significant reductions in thickness incrementally with each successive forming stage.

Enhances accuracy.

The progressive nature of deep drawing means that each cavity is well-formed before forming forces act over increasingly broad cross-sections of the material. This maximizes part accuracy as compared to other techniques, where initial forming could be limited because of poor tool penetration or restricted mobility at shallow depths.

Summing Up

Deep drawing involves progressive metalworking that enables exceptional dimensional accuracy using a single set of dies. It is well-suited for producing intricate or complicated profiles with fine details, which are subsequently formed into asymmetric shapes. The benefits of the process are clear because no secondary machining operations are required.

One Response

It’s great that you mentioned how deep draw metal stamping is suitable for low-cost materials like steel, copper alloys, aluminum alloys, magnesium alloys, and brass. I was watching a TV show about manufacturing the other day and I learned about deep draw stamping. I didn’t know that such a manufacturing process actually exists, but it looks quite useful.