Discover the myriad products birthed from the process of metal stamping, a pivotal manufacturing technique. In this article, we will traverse through various industries, unveiling the integral role of metal stamping in crafting essential components.

Metal stamping crafts components for industries like automotive, electronics, aerospace, and more. It’s a vital process in fabricating durable and precise parts in various sectors.

Join us as we delve deeper, offering you a comprehensive view of the products created through metal stamping, and the nuances of the process that brings them to life.

Delving Into the World of Metal Stamping

In the dynamic landscape of manufacturing, metal stamping stands as a cornerstone, facilitating the creation of a myriad of products that permeate various industries. From the automotive sector to the burgeoning field of new energy vehicles, metal stamping plays a pivotal role in shaping the future of innovation and sustainability.

Metal stamping, a process that involves the use of dies to transform flat metal sheets into various shapes and forms, is renowned for its precision and efficiency. This manufacturing technique is instrumental in crafting components that are not only durable but also adhere to the highest standards of quality and precision.

As we delve deeper into the world of metal stamping, we uncover its significant contributions across different sectors. Let’s embark on this journey to explore the intricate components crafted through metal stamping in industries such as automotive, electronics, household appliances, aerospace, medical devices, and new energy vehicles. Through this exploration, we will witness the remarkable impact of metal stamping in fostering innovation and propelling industries towards new heights of excellence.

In the subsequent sections, we will dissect the role of metal stamping in each of these sectors, highlighting the components made through this process and discussing case studies that showcase the immense potential of metal stamping in revolutionizing manufacturing and fostering sustainability.

Automotive Parts: Unveiling the significance of metal stamping in the automotive industry.

In the dynamic world of the automotive industry, the manufacturing process is a cornerstone that holds immense significance. One of the pivotal processes that stand central to manufacturing is metal stamping. This technique is renowned for crafting various components with high precision and durability, playing a crucial role in building vehicles that are both reliable and efficient.

Components Made:

Metal stamping is instrumental in crafting a myriad of automotive parts, including but not limited to:

- Body Panels: These are the external surfaces of vehicles, including doors, hoods, and fenders, which are often crafted using metal stamping for a sleek finish and durability.

- Engine Components: Various engine parts such as pistons and connecting rods are made using metal stamping, ensuring high precision and reliability.

- Transmission Parts: Components like gears and clutches, which are central to a vehicle’s transmission system, are crafted using this technique, ensuring smooth vehicle operation.

- Exhaust Parts: Elements like exhaust manifolds and mufflers are also created using metal stamping, contributing to a vehicle’s overall performance and safety.

Benefits:

The utilization of metal stamping in automotive manufacturing comes with a plethora of benefits:

- Cost-Efficiency: Metal stamping allows for mass production of parts with minimal waste, making it a cost-effective choice.

- Precision and Quality: This technique ensures that the parts are manufactured with high precision, maintaining a consistent quality across all components.

- Durability: Metal stamped parts are known for their durability, capable of withstanding harsh conditions and ensuring a longer lifespan for the vehicle.

- Versatility: Metal stamping can be used to create a wide variety of parts, showcasing its versatility in meeting diverse manufacturing needs.

Case Study/Example:

A notable example of a company utilizing metal stamping extensively is Tesla, Inc. In the manufacturing of their electric vehicles, Tesla employs advanced metal stamping techniques to create body panels and other components. Their Gigafactory in Fremont, California, houses one of the largest metal stamping presses in the world, capable of exerting a force of over 40,000 tons. This allows Tesla to produce high-quality, durable, and aesthetically pleasing vehicle components, showcasing the immense potential and significance of metal stamping in the modern automotive industry.

Electronics Components: Exploring the intricate components in electronics crafted through metal stamping.

In the ever-evolving sector of electronics, the demand for components that are both precise and reliable is at an all-time high. Metal stamping stands as a beacon in this sector, offering a method to craft intricate components with high precision and reliability. This manufacturing process is pivotal in the creation of a myriad of electronic components that find their place in various gadgets and devices we use daily.

Components Made:

Metal stamping plays a significant role in crafting various electronic components, including:

- Connectors: These are essential components that facilitate the connection between different parts of an electronic device. Metal stamping ensures they are crafted with precision to allow seamless connectivity.

- Heat Sinks: These components are crucial in dissipating heat generated by electronic devices. Metal stamping helps in crafting heat sinks with intricate designs for efficient heat dissipation.

- Shields: Metal stamping is used to create shields that protect sensitive electronic components from electromagnetic interference, ensuring the smooth functioning of the device.

- Terminals: These are components used to establish connections in an electronic circuit. Metal stamping ensures that terminals are crafted with high precision for reliable connections.

Precision and Reliability:

Metal stamping stands as a cornerstone in ensuring the precision and reliability of electronic components. The process allows for the creation of components with intricate designs and tight tolerances, ensuring a high level of accuracy. Moreover, the use of high-quality materials in metal stamping guarantees the reliability of the components, ensuring a longer lifespan and efficient performance in electronic devices.

Case Study/Example:

A quintessential example of a popular electronic product that utilizes components made through metal stamping is the smartphone. Companies like Apple employ metal stamping techniques extensively in the manufacturing of various components found in the iPhone. From the connectors that facilitate seamless communication between different parts of the phone to the shields that protect sensitive components, metal stamping plays a vital role in crafting components that are both reliable and precise, contributing to the overall performance and functionality of the device.

Appliance Parts: A look into how household appliances benefit from metal stamping.

The household appliance industry is a sector that constantly seeks innovation and efficiency. From refrigerators to washing machines, the appliances that facilitate our daily lives are a testament to engineering excellence. Metal stamping plays a significant role in this sector, being instrumental in crafting various components that not only enhance the durability but also the efficiency of these appliances.

Components Made:

Metal stamping is utilized extensively in the manufacturing of a wide array of appliance parts, including:

- Housings: The external bodies of various appliances are crafted using metal stamping, ensuring durability and a sleek finish.

- Motor Cores: These are central components in many appliances, facilitating the functioning of motors. Metal stamping ensures they are crafted with precision and reliability.

- Brackets: These components are used to support various parts within an appliance, and metal stamping ensures they are strong and durable.

- Fan Blades: In appliances like air conditioners and refrigerators, fan blades are crafted using metal stamping to ensure efficiency and optimal performance.

Durability and Efficiency:

Metal stamping significantly contributes to the durability and efficiency of household appliances. The process allows for the crafting of components with high precision, ensuring a snug fit and optimal performance. Moreover, the use of high-quality materials in metal stamping ensures the durability of the components, allowing appliances to withstand wear and tear over time, thereby extending their lifespan. Furthermore, the efficiency of appliances is enhanced as metal stamping allows for the creation of components that facilitate optimal performance, reducing energy consumption and promoting sustainability.

Case Study/Example:

A notable example of a well-known appliance brand that relies heavily on metal stamping for manufacturing parts is Whirlpool Corporation. This global leader in the appliance industry utilizes advanced metal stamping techniques to create various components found in their range of products, from washing machines to refrigerators. The precision and durability ensured by metal stamping techniques are evident in the high-quality and reliable appliances that the company produces, showcasing the vital role of metal stamping in the household appliance industry.

Aerospace Parts: Understanding the role of metal stamping in the aerospace sector.

The aerospace sector, a realm where innovation meets excellence, stands as a testament to human ingenuity. In this sector, the emphasis on safety and precision is unparalleled. Metal stamping emerges as a vital process in this context, facilitating the creation of components that not only adhere to stringent safety standards but also embody precision, a hallmark of aerospace engineering.

Components Made:

Metal stamping is instrumental in crafting a variety of aerospace components, including:

- Engine Components: Various components within aircraft engines, such as turbine blades and combustion chambers, are crafted using metal stamping, ensuring high precision and reliability.

- Structural Components: Elements like fuselage frames and wing ribs are created using metal stamping, providing the necessary structural integrity to the aircraft.

- Landing Gear Components: Parts like struts and shock absorbers, which are essential to the landing gear system, are manufactured using metal stamping techniques, ensuring safety and durability.

- Instrument Panels: The instrument panels in the cockpit, housing various controls and indicators, are crafted using metal stamping, ensuring precision and reliability in the flight control system.

Safety and Precision:

In the aerospace sector, the emphasis on safety and precision is paramount. Metal stamping plays a critical role in ensuring these aspects. The process allows for the creation of components with intricate designs and tight tolerances, meeting the stringent safety standards set by the industry. Moreover, the high precision achieved through metal stamping ensures the reliable functioning of various components, a vital aspect in maintaining the safety and efficiency of aerospace operations.

Case Study/Example:

A notable example in the aerospace sector that utilizes metal stamping extensively is Boeing, a global leader in aerospace manufacturing. Boeing employs advanced metal stamping techniques in various projects, including the manufacturing of components for commercial jetliners like the Boeing 787 Dreamliner. The use of metal stamping allows for the creation of components that are both lightweight and durable, meeting the high standards of safety and precision that are synonymous with aerospace engineering. This showcases the significant role of metal stamping in propelling the aerospace sector towards new heights of innovation and excellence.

Medical Device Components: Analyzing the precision and reliability of medical components made through metal stamping.

The medical device industry stands as a beacon of innovation and precision, constantly evolving to meet the growing demands of healthcare. In this sector, the role of metal stamping is pivotal, facilitating the creation of components that are not only precise but also reliable. This manufacturing process is central to crafting various medical devices that are instrumental in enhancing healthcare delivery and patient outcomes.

Components Made:

Metal stamping is utilized extensively in the manufacturing of a wide array of medical device components, including:

- Surgical Instruments: Various instruments used in surgeries, such as forceps and clamps, are crafted using metal stamping, ensuring precision and reliability.

- Implantable Devices: Components for devices like pacemakers and joint replacements are created using metal stamping, ensuring they are crafted with the highest level of precision and quality.

- Diagnostic Equipment: Parts for diagnostic devices like MRI machines and X-ray equipment are manufactured using metal stamping techniques, ensuring high reliability and functionality.

- Dental Instruments: Various instruments used in dentistry, including dental forceps and scalers, are crafted using metal stamping, ensuring durability and precision.

Precision and Reliability:

In the medical device industry, the emphasis on precision and reliability is paramount. Metal stamping plays a significant role in ensuring these aspects. The process allows for the crafting of components with intricate designs and tight tolerances, meeting the stringent standards set by the industry. Moreover, the high-quality materials used in metal stamping ensure the reliability of the components, a vital aspect in maintaining the safety and efficacy of medical devices.

Case Study/Example:

A notable case where metal stamping played a crucial role in manufacturing a medical device is in the creation of cardiovascular stents. Companies like Medtronic utilize advanced metal stamping techniques to craft stents with high precision. These stents are used to keep arteries open and facilitate blood flow, playing a vital role in the treatment of cardiovascular diseases. The precision and reliability ensured by metal stamping techniques are evident in the high success rates of stent implantations, showcasing the immense potential and significance of metal stamping in the medical device industry.

NEV (New Energy Vehicles): Discussing the contribution of metal stamping in the burgeoning field of new energy vehicles.

The field of new energy vehicles (NEVs) represents a significant shift towards sustainable and innovative transportation solutions. As the industry burgeons, the role of metal stamping has become increasingly pivotal. This manufacturing process facilitates the creation of various components integral to the structure and functionality of NEVs, thereby playing a crucial role in shaping the future of transportation.

Components Made:

Metal stamping is instrumental in crafting a myriad of components found in NEVs, including:

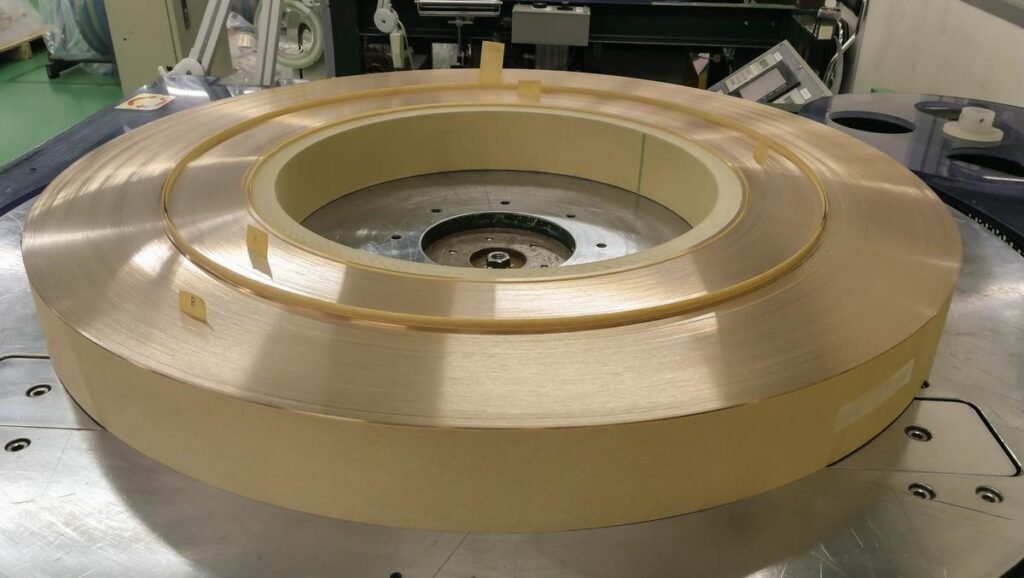

- Battery Trays: These are specially designed trays to house the batteries that power NEVs. Metal stamping ensures they are crafted with precision and durability to safely secure the batteries.

- Motor Casings: The casings that house the electric motors in NEVs are created using metal stamping, ensuring protection and optimal functioning of the motors.

- Chassis Components: Various components that form the chassis of NEVs are crafted using metal stamping, providing the necessary structural integrity and safety to the vehicles.

- Cooling Systems: Components for cooling systems, essential in managing the heat generated by electric motors, are manufactured using metal stamping, ensuring efficiency and reliability.

Innovation and Sustainability:

Metal stamping stands at the forefront of fostering innovation and sustainability in the NEV sector. The process allows for the creation of components with complex designs and high precision, facilitating the development of advanced and efficient NEVs. Moreover, metal stamping contributes to sustainability by enabling the mass production of components with minimal waste, thereby promoting resource efficiency and reducing the environmental impact of vehicle manufacturing.

Case Study/Example:

A prime example of a company that extensively utilizes metal stamping in the NEV sector is Tesla, Inc. This trailblazer in the electric vehicle industry employs advanced metal stamping techniques in the manufacturing of various components for their electric cars. For instance, in the production of their Model 3 sedan, Tesla utilizes metal stamping for crafting intricate components like the battery trays and motor casings, showcasing the significant role of metal stamping in fostering innovation and sustainability in the NEV industry.

The Basics of Metal Stamping

In the intricate world of manufacturing, understanding the foundational processes is pivotal. One such process that stands central to the creation of a myriad of products across various industries is metal stamping. This technique, characterized by its precision and efficiency, transforms flat metal sheets into specific shapes and forms, ready to be assembled into final products. As we venture into the basics of metal stamping, we will explore its definition and the processes involved, delve into the techniques utilized, examine the materials shaped through this process, and discuss the benefits and potential challenges that come with it. Let’s embark on this journey to unravel the nuances of metal stamping, a process that significantly contributes to the modern manufacturing landscape.

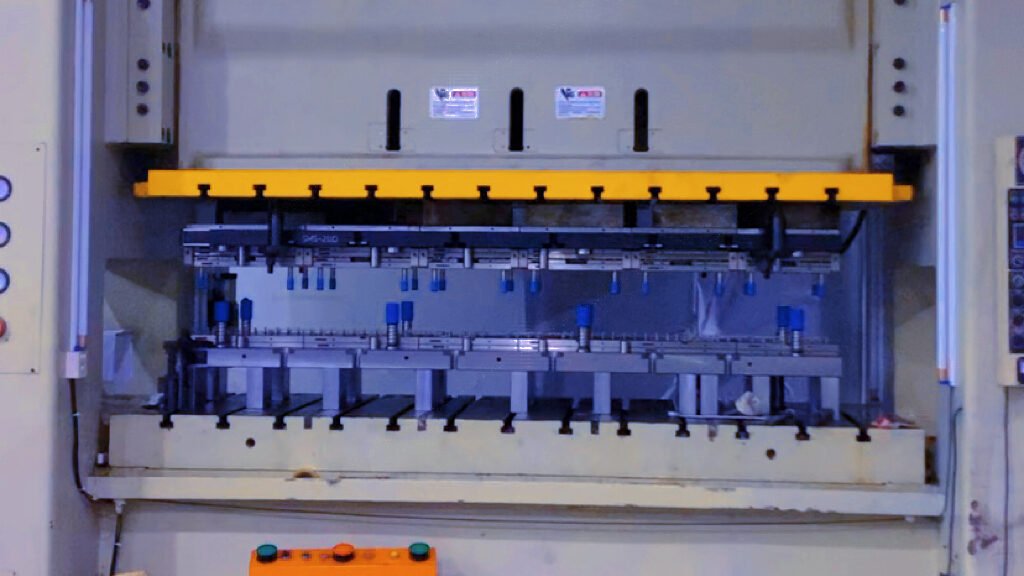

Definition and Process

Metal stamping is a manufacturing process that involves the use of specialized dies and stamping presses to transform flat metal sheets into specific shapes and forms. This process encompasses a series of stages including blanking, punching, bending, and embossing, which are carried out in a systematic manner to craft intricate components with high precision. The versatility of metal stamping makes it a preferred choice in various industries, offering a reliable solution for mass-producing high-quality parts.

Techniques Involved

In the realm of metal stamping, several techniques are employed to achieve the desired outcomes. These include:

- Blanking: A process where pieces are cut from a sheet of metal, which will then be used in further processes.

- Punching: Similar to blanking, but here the removed piece is scrap, and the remaining sheet is the desired part.

- Bending: This involves bending the metal sheet to a desired angle and shape.

- Deep Drawing: A process where the metal sheet is drawn into a forming die by a mechanical punch.

- Coining: A precision stamping process that involves a substantial amount of force to alter the surface of the material.

These techniques can be used singularly or in combination, depending on the complexity of the component being manufactured.

Materials Used

A wide range of metals can be used in the stamping process, depending on the desired properties and application of the final product. Some of the most commonly used metals include:

- Steel: Known for its durability and strength, steel is often used for automotive parts, construction materials, and many other applications.

- Aluminum: Lightweight and resistant to corrosion, aluminum is frequently used in the aerospace industry, automotive components, and household products.

- Brass: With its golden appearance, brass is often chosen for decorative items, musical instruments, and certain electrical applications due to its conductivity.

- Copper: Valued for its electrical conductivity, copper is commonly used in electrical components, wiring, and decorative items.

- Stainless Steel: This corrosion-resistant alloy is used in a variety of applications, from kitchenware to medical instruments.

- Zinc: Often used in the die-casting process, zinc is known for its ability to resist corrosion and is commonly found in automotive components and hardware.

Each metal offers unique properties, making it suitable for specific applications. The choice of material often depends on factors such as strength, weight, cost, and aesthetic appeal.

Benefits and Challenges

Metal stamping comes with a host of benefits including high precision, cost-effectiveness, and the ability to mass-produce components with consistent quality. However, it also presents certain challenges such as the initial high setup costs and the requirement for specialized dies for different components. Moreover, the process can sometimes be limited in terms of the complexity of designs it can handle. Despite these challenges, the advantages of metal stamping often outweigh the downsides, making it a vital process in modern manufacturing.

Conclusion

As we reach the culmination of our exploration into the world of metal stamping, it is evident that this manufacturing process stands as a linchpin in various industries, fostering innovation and sustainability. From delving into its significant contributions in sectors such as automotive, electronics, household appliances, aerospace, medical devices, and new energy vehicles, we have witnessed the remarkable versatility and efficiency that metal stamping brings to the table. Moreover, our journey into the basics of metal stamping has shed light on the intricate processes, techniques, and materials that characterize this manufacturing method. As we forge ahead into a future where precision and sustainability are paramount, metal stamping promises to continue playing a pivotal role in shaping the landscape of modern manufacturing.

FAQ

- What is metal stamping?

Metal stamping is a manufacturing process that utilizes specialized dies and presses to transform flat metal sheets into specific shapes and forms, commonly used in various industries for creating high-quality components.

- What industries benefit from metal stamping?

Numerous industries benefit from metal stamping, including automotive, electronics, household appliances, aerospace, medical devices, and new energy vehicles, where it is used to create a wide array of components.

- What materials are commonly used in metal stamping?

The materials commonly used in metal stamping include steel, aluminum, copper, and brass, each chosen based on their specific properties and the requirements of the final product.

- What are the benefits and challenges of metal stamping?

Metal stamping offers benefits such as high precision, cost-effectiveness, and the ability to mass-produce components with consistent quality. However, it also presents challenges like high initial setup costs and limitations in handling complex designs.

- Can metal stamping be used for complex component designs?

While metal stamping is capable of creating components with intricate designs, extremely complex designs might require additional processes or techniques to achieve the desired outcome.