Discover the intricate world of precision pressing in electronics. Dive deep into the craftsmen, engineers, and the technology behind this essential component in modern electronic devices.

Precision pressing stands at the intersection of craftsmanship and engineering, essential for the assembly of electronic components with the highest degree of accuracy. This process is crucial for the seamless performance of electronic devices.

We invite you to explore the nuances of precision pressing, understand its critical role, and consider its influence on the electronics industry.

Who are the craftsmen and engineers behind this precision pressing for electronics?

In the intricate domain of electronics, precision pressing emerges as a discipline that demands both artistry and technical prowess, uniting the dexterity of seasoned craftsmen with the acumen of adept engineers. But what defines these specialists, and what roles do they fulfill within the meticulous sphere of precision pressing?

Profiling the Specialists Behind Precision Pressing

At its core, precision pressing transcends the boundaries of equipment and automation; it’s fundamentally about the experts who endow these tools with purpose and precision. This field’s specialists are an amalgamation of time-honored craftsmen, with years of refined practice, and contemporary engineers, equipped with cutting-edge solutions for intricate problems. These professionals hail from varied experiences but are united by a singular ambition: the pursuit of flawlessness in every component they fashion.

The Artisan’s Contribution to Precision Pressing

Craftsmen are the cornerstone of the precision pressing process. Their meticulous attention to detail and profound knowledge of materials guarantee that each component is produced to the most precise standards. Their tactile expertise, paired with a wealth of experience, enables them to identify and rectify even the most minuscule flaws. To these artisans, precision pressing is more than mere work—it is a form of expression, where each part is a testament to their mastery and dedication to excellence.

The contribution of engineers in enhancing the technology

While craftsmen bring the art to precision pressing, engineers infuse it with cutting-edge technology. They are the brains behind the advanced machinery and processes that make precision pressing possible at a large scale. By constantly researching and developing new techniques, engineers ensure that the pressing process remains efficient, accurate, and up-to-date with the latest technological advancements. Their analytical skills and innovative mindset have led to breakthroughs that have revolutionized the world of precision pressing.

Together, craftsmen and engineers form the backbone of the precision pressing industry, ensuring that electronic devices are equipped with components of the highest quality and precision.

What kinds of electronic devices benefit the most from precision-pressed parts?

In today’s technologically driven world, electronic devices are an integral part of our daily lives. From the smartphones we can’t live without to the advanced medical equipment that saves lives, the role of precision-pressed parts is undeniable. But which devices benefit the most from these meticulously crafted components?

Overview of devices that rely heavily on precision-pressed components

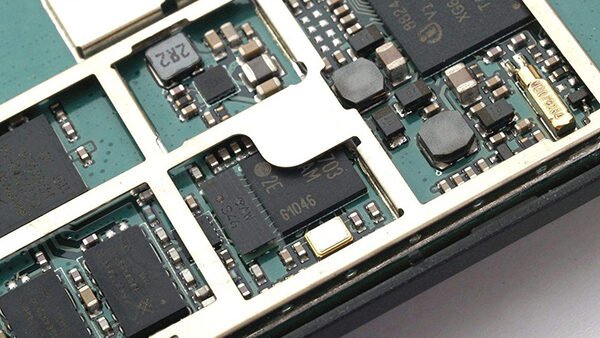

- Smartphones and Tablets: These everyday gadgets are packed with tiny components that need to fit perfectly to ensure optimal performance. Precision-pressed parts play a crucial role in the assembly of microchips, camera modules, and battery connectors.

- Computers and Laptops: The central processing units (CPUs), memory chips, and various connectors inside these devices require precision-pressed parts to ensure seamless data transfer and processing.

- Wearable Tech: Devices like smartwatches and fitness trackers, with their compact design, rely heavily on precision-pressed components to deliver accurate health metrics and notifications.

- Medical Equipment: Advanced medical devices, such as MRI machines, pacemakers, and surgical robots, utilize precision-pressed parts to ensure accuracy and reliability during critical procedures.

- Automotive Electronics: Modern vehicles come equipped with numerous electronic systems for navigation, entertainment, and safety. These systems depend on precision-pressed components for efficient performance.

- Aerospace and Defense: Satellites, drones, and advanced defense systems require components that can withstand extreme conditions. Precision pressing ensures these parts are durable and reliable.

The significance of precision pressing in ensuring device functionality

The functionality of an electronic device is only as good as its components. Precision-pressed parts ensure that each component fits perfectly, operates efficiently, and lasts longer. Any compromise in the quality or accuracy of these parts can lead to device malfunctions, reduced lifespan, or even safety hazards. For instance, a smartphone with a poorly pressed connector might suffer from frequent signal drops, while a medical device with imprecise components could jeopardize patient safety. Hence, precision pressing is not just about achieving perfection; it’s about ensuring that electronic devices fulfill their intended purpose efficiently and safely.

In conclusion, precision-pressed parts are the unsung heroes behind the seamless operation of countless electronic devices. Their importance might often be overlooked, but their impact on device functionality and reliability is undeniable.

When did the integration of precision-pressed parts become a standard in electronic device manufacturing?

The advent of precision-pressed components within electronic device production is the result of a progressive series of developments, rooted in persistent innovation, thorough research, and leaps in technological progress. We’ll explore the historical context and key developments that have influenced the evolution of precision pressing in the electronics sector.

Tracing the Evolution of Precision Pressing in Electronics

Precision pressing’s legacy stretches back to the dawn of the 20th century, coinciding with the nascent stages of the electronics industry. As the form factor of electronic devices transformed from the bulky and basic to the sleek and complex, the demand for components with exacting precision surfaced. Initially, precision pressing was a largely manual endeavor, with skilled craftsmen employing hand tools and rudimentary machinery to fashion metal parts to their required specifications.

However, the period following World War II signified a critical juncture. The electronics revolution, spurred by the introduction of transistors and integrated circuits, rendered the manual techniques insufficient. It was during the 1960s and 1970s that automation began to take center stage, with industry players embracing sophisticated machinery and technology to satisfy the escalating requirements for precision-pressed parts, a trend that has continued to advance into the complex, high-tech methodologies of today.

Milestones in the evolution of precision pressing technology

- Introduction of Hydraulic Presses (1950s): The hydraulic press, capable of exerting immense pressure, revolutionized the precision pressing process, allowing for the production of intricate parts with high accuracy.

- Advent of Computer Numerical Control (CNC) Machines (1970s): The introduction of CNC machines brought about unparalleled precision and consistency in the pressing process. These machines, controlled by computerized systems, could produce parts with intricate designs and tight tolerances.

- Integration of Robotics (1980s): The 1980s saw the integration of robotic arms in the pressing process, enhancing efficiency and reducing human error. Robots could handle delicate components with precision, ensuring consistent quality.

- Development of Micro Precision Pressing (1990s): With the rise of microelectronics, there was a need for micro-sized components. Micro precision pressing technology emerged to cater to this demand, enabling the production of parts as small as a few micrometers.

- Incorporation of Artificial Intelligence (2010s): The recent decade has witnessed the integration of AI in precision pressing. AI-powered machines can predict and correct errors in real-time, optimize the pressing process, and ensure the highest level of accuracy.

Today, precision pressing is an indispensable part of electronic device manufacturing. The journey from manual crafting to AI-driven precision pressing is a testament to human ingenuity and the relentless pursuit of perfection. As technology continues to evolve, precision pressing will undoubtedly play a pivotal role in shaping the future of electronics.

Where are these precision-pressed parts produced, and where do they find their most significant applications?

The global demand for precision-pressed parts has led to the establishment of production hubs worldwide. These parts, integral to various industries, have found applications that range from everyday gadgets to critical aerospace components. Let’s explore the leading production centers and the sectors that predominantly utilize these components.

Leading production hubs for precision-pressed parts

- East Asia: Nations such as Japan, South Korea, and Taiwan spearhead advancements in precision pressing technologies. Their sophisticated manufacturing ecosystems, bolstered by a commitment to research and innovation, position them as global pioneers in the fabrication of premium precision-pressed components.

- China: In recent years, China has ascended as a pivotal center for the manufacture of electronic components. Leveraging an expansive industrial framework and efficient production methods, China has become a significant producer of precision-pressed parts for the global market.

- Germany: Germany’s reputation for its engineering excellence extends to its contributions in the field of precision pressing. It plays a crucial role, particularly within the realms of automotive and industrial manufacturing, due to its precision engineering capabilities.

- United States: With a rich history of industrial innovation, the US houses several leading companies specializing in precision pressing, catering to sectors like aerospace, defense, and consumer electronics.

- Scandinavian Countries: Nations like Sweden and Finland have made notable contributions to precision pressing, particularly in telecommunications and automotive industries.

Industries and sectors where these components are predominantly used

- Consumer Electronics: Precision-pressed parts are essential in smartphones, tablets, laptops, and other consumer gadgets. They ensure device functionality, longevity, and performance.

- Automotive: Modern vehicles, with their advanced electronic systems, rely heavily on precision-pressed components for sensors, infotainment systems, and safety features.

- Aerospace and Defense: The aerospace industry requires components that can withstand extreme conditions. Precision-pressed parts ensure reliability in aircraft systems, satellites, and defense equipment.

- Medical Devices: Precision is paramount in medical equipment. Devices like pacemakers, surgical robots, and diagnostic machines utilize precision-pressed components to ensure accuracy and patient safety.

- Telecommunications: The telecom industry, with its network equipment, routers, and switches, depends on precision-pressed parts for seamless data transmission and connectivity.

- Industrial Automation: As industries move towards automation, robots and automated machinery equipped with precision-pressed components play a crucial role in enhancing production efficiency.

In conclusion, precision-pressed parts, with their unparalleled accuracy and quality, have found applications in almost every sector. As technology continues to advance, the significance of these components will only grow, reinforcing their importance in shaping the future of various industries.

Why is precision pressing so vital for the functionality and reliability of electronic devices?

The intricate world of electronics hinges on the precision and reliability of its components. At the heart of this precision lies the art and science of precision pressing. But what makes it so crucial for electronic devices, and how does it ensure their optimal functionality and longevity?

The science behind precision pressing

Precision pressing is an intricate manufacturing technique that molds metal or various materials into parts with precise dimensions. This process is underpinned by a synergy of material science, engineering tenets, and cutting-edge technology.

- Material Science: The unique characteristics of different materials are pivotal in precision pressing. This method guarantees the optimization of the material’s innate qualities, such as malleability, conductivity, and strength, tailored to their specific use.

- Engineering Principles: The process is meticulously guided by engineering principles to ensure components achieve optimal efficiency and functionality. Considerations include managing stress forces, accommodating thermal dynamics, and mitigating electromagnetic disruptions.

- Advanced Technology: Modern precision pressing employs state-of-the-art machinery, often controlled by computer algorithms, to achieve unparalleled accuracy. These machines can produce components with tolerances as tight as a few micrometers.

How precision pressing ensures device longevity and reliability

- Fit and Function: Precision-pressed parts fit perfectly within electronic devices, ensuring seamless integration. A component that fits well will function optimally, reducing the chances of malfunctions.

- Durability: Components produced through precision pressing are designed to withstand wear and tear. Their durability ensures that devices don’t break down prematurely.

- Thermal Management: Electronic devices generate heat, and precision-pressed components are designed to manage this heat effectively. Proper thermal management ensures that devices don’t overheat, thus prolonging their lifespan.

- Electromagnetic Compatibility: In our interconnected world, electronic devices often operate in close proximity. Precision-pressed parts ensure that devices don’t interfere with each other’s operations, ensuring reliable performance.

- Cost-Efficiency: While precision pressing might seem expensive initially, in the long run, it proves cost-effective. Devices with precision-pressed components have fewer breakdowns and require less maintenance, saving costs for manufacturers and consumers.

At its core, precision pressing plays a pivotal, though often overlooked, role in the smooth functioning of electronic devices. It is key to ensuring that these devices operate flawlessly and endure over time. With the continual advancement of electronic devices, the importance of precision pressing in maintaining their performance and dependability is set to become even more crucial.

How does the precision pressing process work, and how has it evolved with technological advancements?

Precision pressing is an essential element in the fabrication of modern electronics, having evolved substantially through technological progress. The process involves a series of meticulous steps, each critical to the final product’s functionality and quality.

Detailed Overview of the Precision Pressing Procedure

- Material Selection: Everything starts with choosing the right material that suits the required attributes and the specific use of the final product, whether it’s a metal, an alloy, or a sophisticated composite.

- Design and Prototyping: Using advanced CAD software, engineers design the component. A prototype is then crafted to validate the design, ensuring it meets all functional prerequisites.

- Die Fabrication: The creation of the die is a crucial step. This specialized tool is engineered to exact design specifications and is instrumental in shaping the material into the final component.

- Pressing Process: The material is positioned within the pressing apparatus, where the die meticulously molds it into shape. The method of pressing—whether stamping, forging, or another technique—depends on the material’s characteristics and the complexity of the design.

- Heat Treatment: Post-pressing, materials often undergo heat treatment to augment their properties, such as increasing their strength or hardness, to meet stringent quality standards.

- Finishing: After pressing, the component undergoes finishing processes like polishing, coating, or plating to enhance its appearance and protect it from corrosion.

- Quality Control: The final component is subjected to rigorous quality checks to ensure it meets the desired specifications and standards.

Technological innovations that have revolutionized precision pressing

- Computer-Aided Design (CAD): The introduction of CAD software has transformed the design phase, allowing for intricate designs and rapid prototyping.

- Computer Numerical Control (CNC) Machines: CNC machines, controlled by computer algorithms, offer unparalleled precision and consistency in the pressing process.

- 3D Printing: This technology has revolutionized prototyping, enabling engineers to create accurate 3D models of the component before actual production.

- Laser Cutting and Etching: Lasers provide high precision in cutting and shaping materials, especially for intricate designs.

- Artificial Intelligence (AI) and Machine Learning: These technologies are being integrated into pressing machines to predict and correct errors in real-time, optimize the pressing process, and ensure the highest level of accuracy.

- Robotics: The integration of robotic arms has enhanced efficiency, reduced human error, and allowed for the production of components at a faster rate.

- Advanced Material Science: The development of new alloys and composites has expanded the possibilities in precision pressing, allowing for components with enhanced properties.

In conclusion, the precision pressing process, backed by continuous technological advancements, has evolved to meet the ever-growing demands of the electronics industry. As technology continues to progress, precision pressing will undoubtedly adapt and innovate, ensuring that it remains at the forefront of electronic component manufacturing.

Conclusion

The electronics industry is expansive and continually advancing, marked by a rapid pace of innovation. Central to this vibrant sector is the discipline of precision pressing, which is integral in guaranteeing that electronic devices operate effectively, remain dependable, and have extended durability.

Summarizing the importance of precision pressing in the electronic industry: Precision pressing stands as the backbone of electronic manufacturing. From the tiniest microchips in our smartphones to the intricate components in aerospace equipment, precision-pressed parts play a pivotal role. They ensure that devices operate seamlessly, last longer, and deliver optimal performance. The meticulous attention to detail, accuracy, and quality assurance in the precision pressing process underscores its significance in the electronics industry.

A look into the future: upcoming trends and advancements in precision pressing:

- Integration of Advanced AI: As AI continues to evolve, its integration into precision pressing machines will enhance real-time monitoring, predictive maintenance, and optimization of the pressing process.

- Sustainable Materials: With a growing emphasis on sustainability, the future might see the use of eco-friendly materials in precision pressing, reducing the environmental impact.

- Nano Precision Pressing: As devices become more compact, there will be a push towards nano precision pressing, allowing for the production of components at a nanoscale level.

- Smart Factories: The concept of Industry 4.0 will transform precision pressing factories into smart factories, where machines, devices, and humans will communicate and collaborate in real-time.

- Customization and Personalization: With advancements in 3D printing and rapid prototyping, there might be a trend towards more customized and personalized precision-pressed components.

In wrapping up, precision pressing, with its rich history and promising future, remains a cornerstone in the world of electronics. As we look ahead, it’s evident that this process, backed by technological advancements, will continue to shape the future of electronic devices, ensuring they are more efficient, reliable, and innovative.

FAQ

Q: What materials are commonly used in precision pressing?

A: Metals, alloys, and composites are the primary materials, with the choice depending on the desired properties and application.

Q: How has AI impacted precision pressing?

A: AI has enhanced real-time error detection, process optimization, and predictive maintenance in precision pressing.

Q: Are there any environmental concerns related to precision pressing?

A: While the process itself is efficient, there’s a push towards using sustainable materials and reducing waste to make it more eco-friendly.